News Navigation

The use of odorless E0 grade environmentally friendly particleboard for desk production is mainly based on three core requirements: environmental safety, performance adaptation, and controllable cost. Its advantages can be analyzed in depth from dimensions such as material characteristics, usage scenarios, and industry standards

1、 The core value of E0 environmental protection standard: safeguarding indoor health

1. Strict control of formaldehyde emissions

Industry standard comparison:

E0 level: According to GB/T 39600-2021 "Classification of formaldehyde emissions from artificial boards and their products", the formaldehyde emissions are ≤ 0.050mg/m 3, which is close to natural wood (pine wood formaldehyde emissions are about 0.03-0.06mg/m 3), and belongs to the relatively high environmental protection level of indoor building materials at present.

E1 level: Formaldehyde emission ≤ 0.124mg/m 3, which meets the national standard but is still higher than E0 level. It is mostly used in non enclosed spaces (such as wardrobes and floors).

Unqualified board: Some inferior particleboard can release formaldehyde at a concentration of over 0.5mg/m 3, which can cause dizziness, allergies, and even cancer (World Health Organization Class I carcinogens) if released for a long time.

Odorless essence: E0 grade boards use MDI glue (isocyanate glue) instead of traditional urea formaldehyde resin glue in production. After curing, MDI glue has no free formaldehyde, stable chemical properties, and no unpleasant odor, especially suitable for furniture such as desks that are used up close (users often have their heads down and their breathing area is close to the desktop).

2. Adapt to the usage scenario of the desk

Children's room desk: Children are 2-3 times more sensitive to formaldehyde than childrens. E0 grade board can prevent immune decline and leukemia risk caused by formaldehyde release (according to data from the US Environmental Protection Agency, for every 0.1mg/m 3 increase in indoor formaldehyde concentration, the risk of leukemia in children increases by 24%).

Study/Office Scene: The desk is usually located in a sealed room (such as a bedroom or study), with poor air circulation and low formaldehyde emissions to ensure long-term safety (formaldehyde release cycle can last up to 3-15 years, E0 grade board has low initial release and is easier to control in the later stage).

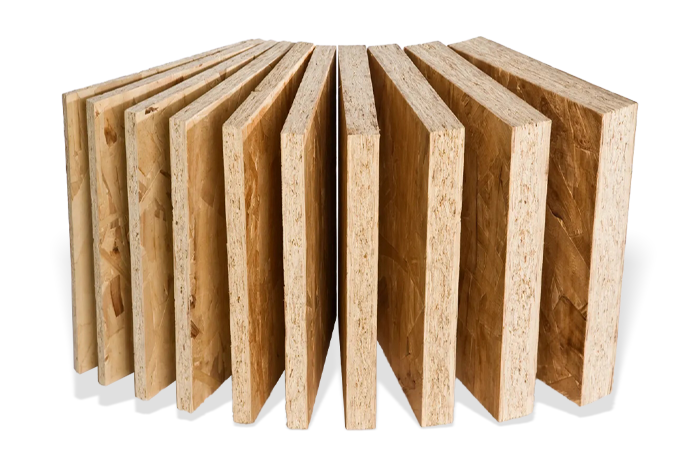

2、 Performance advantages of particleboard: balancing strength, cost, and processability

1. Adapt physical performance to desk functionality

Structural strength: Particle board is made of wood particles that are compressed under high temperature and high pressure (density 650-800kg/m 3). The internal particles are arranged in a staggered manner, with a bending strength of ≥ 15MPa and a desktop load-bearing capacity of ≥ 50kg (able to withstand heavy objects such as computers and books). It is not easily deformed due to moisture (moisture content controlled at 6% -9%, better than the fluctuation range of moisture content of solid wood at 8% -12%).

Surface flatness: The surface of the board can be directly coated with melamine decorative paper or PVC film, which has high flatness and is suitable for writing on desks and placing stationery, avoiding the problem of uneven tabletop caused by the natural texture of solid wood.

2. Processing and cost advantages

Industrial production adaptation: Particle board can be customized in size (common specification 1220 × 2440mm), making it easy to cut, drill, and seal edges. It is suitable for mass production (such as standardized processing of desk drawer bottom and side panels), and the production cost is 30% -50% lower than solid wood.

Moisture proof treatment upgrade: Some E0 grade particleboard is added with moisture-proof particles (such as green moisture-proof layer), and PVC hot melt adhesive is used for edge sealing (sealing strip thickness ≥ 1mm). The waterproof performance is close to that of density board, suitable for occasional contact with water bottles, ink and other scenes on desks.

3、 Industry Trends and Policy Promotion

1. Upgrading environmental standards forces material iteration

After the implementation of the new national standard in 2021, E0 grade has become a standard for furniture, and desks, as the core indoor furniture, have been voluntarily phased out by some companies to meet consumers' health needs.

When purchasing desks in public places such as schools and kindergartens, it is explicitly required to provide E0 level testing reports (such as GB 18580-2017 certification), otherwise they cannot pass the bidding review.

2. Consumer demand orientation

According to a report on furniture consumption trends, 68% of consumers prioritize "environmental grade" when purchasing desks, with a year-on-year increase of 42% in search volume for E0 grade board products. Especially for parents born in the 1980s and 1990s, formaldehyde control in children's room furniture is more important.

Related articles

Home

Home

Wechat

Wechat

Tell

Tell